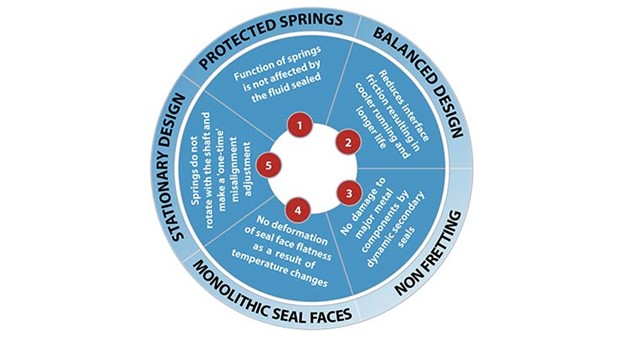

A crucial step in preventative maintenance in pumps is finding and using the correct seal for the job. Mechanical seals are used to seal the rotating shaft in pumps and other equipment. With so many mechanical seal designs on the market, it can be difficult to identify which kinds to use. A.W. Chesterton Company’s mechanical seal design utilizes 5 design principles to maximize its sealing capabilities. These principles have been refined by Chesterton since the company brought its first mechanical seal to market in 1970. After all the lessons learned from successes and failures, they have determined the Five Key Features that a mechanical seal should have to reduce unplanned maintenance and downtime. To provide the greatest mean time between failures (MTBF) and avoid downtime, they utilize these five design principles in their sealing devices.

Protected Springs

Spring protected from fluids | Image provided by A.W. Chesterton Company

Typically, within early mechanical seal designs, the springs were submerged within the fluid. However, this can lead to trouble when fluids with dirt or other contaminates interact with the springs. When the contaminates collect within the spring, it cannot correctly maintain the alignment necessary for a complete seal. Chesterton’s mechanical seal design protects the springs within the mechanical seal from the fluids being pumped.

Balanced Design

The second design feature and open secret of Chesterton’s mechanical seal design is balance. On the mechanical seal, there are two main sides, the fluid side, and the atmospheric side. To prevent moisture from leaking out of the seal, both sides put equal pressure on each other to trap the fluid. Many seals will often see that the fluid side exerts greater pressure than the atmospheric side. Not only does this reduce the quality of the seal, but it can also ruin the pump with time. Balanced seals reduce the seal ring area on which the hydraulic pressure of the liquid in the pump acts. This allows for better lubrication that results in lower heat generation, face wear, and power consumption. Balanced seals will generally have higher pressure ratings than unbalanced seals.

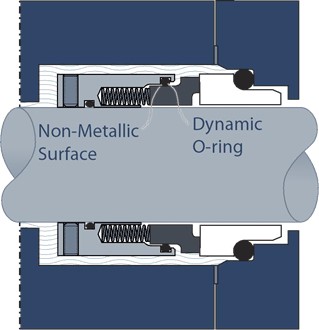

Non-fretting

Non-Fretting Seal | Image provided by A.W. Chesterton Company

Fretting on a pump shaft refers to the way that a material is worn away on a shaft by an elastomeric material. An example may be a 316 stainless steel shaft sleeve that is damaged by a Viton O-ring. Stainless steel protects a shaft from corrosion by forming a chrome oxide layer on the surface. The dynamic O-ring wears that protective surface away and it then reforms. Over time the chrome oxide gets imbedded into the O-ring and works like sandpaper removing even more material. The result is a groove worn into your expensive sleeve and a leaking mechanical seal. Chesterton seals utilize designs that have any dynamic O-rings operating against a non-metallic surface, usually the sacrificial face.

Additionally, some manufacturers offer seals that are self-fretting, rather than shaft-fretting. What this means is that these seals do not fret or damage the shaft, they harm seal itself. While this protects the pumps, the O-rings still work against metal, reducing the lifespan of the seal itself.

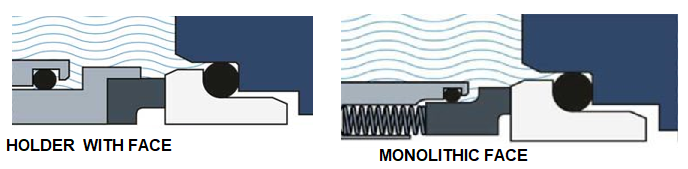

Monolithic Seal Faces

Inserted vs Monolithic Seal Face | Image provided by A.W. Chesterton Company

Some mechanical seal designs utilize an inserted seal face, typically made of carbon or graphite inserted into a metal holder. However, the disadvantage to this technique is these non-metallic materials often react to heat differently than the metal of the seal. The result is the face of the seal is easily deformed- leading to leaks and early replacement of the seal. Proper mechanical seal design uses monolithic seal faces without using a holder and inserted face. By using Finite Element Analysis (computer modeling), Chesterton’s monolithic seal face designs are made more efficiently than ever.

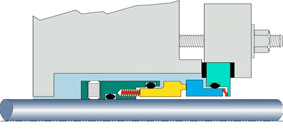

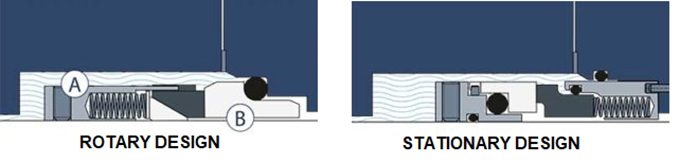

Stationary Design

Rotary vs Stationary Seals | Image provided by A.W. Chesterton Company

Mechanical seals can either use rotating or stationary springs. With rotary mechanical seals, it is important that the stuffing box face is perpendicular to the shaft for the faces to stay closed. There will always be some resulting misalignment from installation and parts tolerances so this alignment cannot be assured. To compensate for the misalignment, the springs must adjust each time the shaft rotates to keep the seal faces closed. At motor speeds this adjustment happens thousands of times per minute (for 1800 rpm, 3600 adjustments occur) which is not only difficult to accomplish, the springs will fatigue and fail causing seal failure. Rotary seals are simple in design which makes them inexpensive

In contrast, a stationary seal is designed in such a way that the springs do not rotate with the pump shaft; they remain stationary. Because the springs do not rotate, they are unaffected by the rotation of the shaft or how fast the shaft rotates. The springs do not need to correct or adjust with each rotation; they adjust for misalignment only once when installed. Chesterton uses this as the fifth design requirement, and this provides greater life to their mechanical seals.

Chesterton 1510L in Action

Using these five design principles, Chesterton has updated its 150 seals to the new 1510 seal. The new design uses a monolithic seal face and changes where the dynamic O-rings are placed to be a non-fretting seal. Chesterton unveiled this updated seal in the US in September of 2022. However, Chesterton also has one additional add-on for this new seal. Starting at the end of October 2022, Chesterton will be releasing the 1510L. The 1510L has all the same design capabilities of the 1510, the difference between the two is the installation process. The 1510L utilizes a lock ring mechanism to simplify installation requiring the installer to tighten only one screw to connect the seal to the shaft.

Next Steps

To request a demonstration for the 1510L mechanical seal, click here. Learn more about Northwest Pump’s mechanical seals by contacting us here, emailing us at sales@nwpump.com, or by calling 1-800-452-PUMP.

For service on your mechanical seals by our Chesterton certified pump technicians, contact us here, email us at service@nwpump.com, or call 1-866-577-2755.