When you are in the market for ISO 8573-1 Class Zero air quality it is important to understand the difference between an “oil-free” air compressor and an “oil-less” air compressor. This is especially critical in the 30HP and under compressor market. “Oil-less” and “oil-free” are not interchangeable terms. The primary differentiator is the presence of oil in the machine and the impact that it has on air quality over time. Here is what you need to know to make the best decision regarding how to achieve your ISO 8573-1 Class Zero compressed air quality.

Rotary Screw Oil-Free Compressors – Almost without exception, an oil-free rotary screw compressor does indeed have oil in it. The oil is sealed in the gear box to provide lubrication to the gears and bearings, but is sealed from the air chamber in order to prevent it from getting into the compressed air stream. As the units age, the seals do harden and wear out due to heat and shelf life. Therefore, as they age, oil will migrate into the air stream and negatively impact air quality. As this happens, air end “slippage” increases and inter-stage temperatures will creep up. Most people do not discover that their air quality has been compromised until the compressor reaches cessation on a high inter-stage temperature shutdown. By then, many pints, quarts or even gallons of oil may have migrated into the process air and piping. Also, most oil free screw compressors (with the exception of the Sullair DSP) have a vented gear box that exasperates oil laden vent air into the compressor, right near the intake filter. The vent on the gearbox adds oil vapors, which are almost immediately sucked back into the air filter and introduced to the air stream. So they are “oil-free” because they do not have oil in the air stream by design. But they are not truly an oil less solution. Mitigation of air contamination, oil maintenance and disposal, and oil leakage containment all must still be considered when applying an oil free rotary screw compressor technology.

Reciprocating Oil-Free Compressors

Reciprocating compressor designs are sold in either oil less or oil free up to about 50HP. They can also be configured into duplex, triplex or quadraplex packages to get up to cover air demands up to about 450 CFM. “Oil-free” compressors in the reciprocating market, like the screw market, do actually have oil in them. They use an extended connecting rod in an extra-tall block known as a “distance piece”. This configuration lengthens the distance between the oil sump and the compression chamber. They usually include extra oil rings as well to help prevent the oil in the crank case from migrating into the air stream. However, over time; oil and compression rings wear out in a reciprocating compressor just like they do in a car engine. So over time, oil will begin to migrate past the rings and into the compression chamber and eventually into the air stream. Most oil free compressor users do not discover their oil contamination problem until they notice a drop in system air pressure related to worn out rings. So once again, the oil free technology still comes at the cost of air and piping contamination, oil maintenance and disposal, and oil leak containment.

Oil-less Reciprocating Compressors

The true oil-less reciprocating compressors, like our Champion V & W, or the MTO II series air compressors have no oil in the crank case at all. They are a 100% true oil-less design and come in simplex, duplex, triplex or quadraplex packages including NFPA 99 compliant packages for hospital grade air. This technology is far more costly, but it provides the true outcome that the customer is aiming for: ISO 8753 Class 0 air quality, and reduced maintenance associated with lubrication systems.

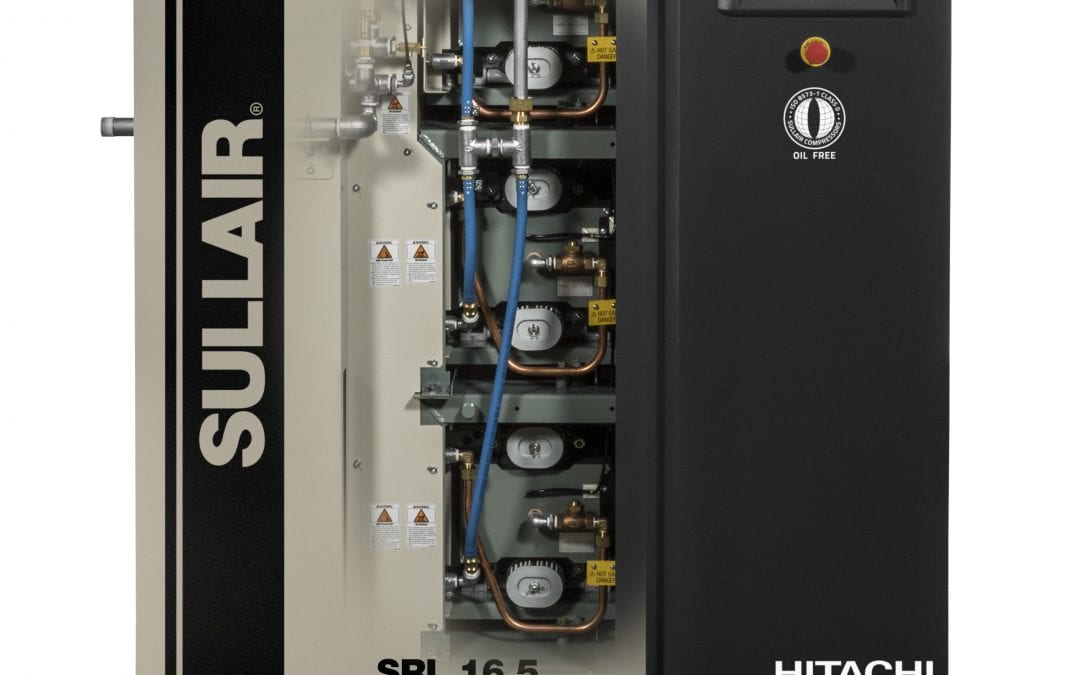

Oil-Free Scroll Compressors

Scroll compressors, like our Sullair model SRL, should really be called oil-less to distinguish them from the oil-free style compressors mentioned above. Like the oil-less reciprocating, the oil less scroll compressors contain no oil at all. They are built on a platform of low maintenance intervals, and guaranteed air quality for life.

If a customer has a critical need for truly Class 0, oil free air quality, they should strongly consider using either an oil less technology like the Sullair SRL scroll package or Champion V & W series. These technologies are admittedly limited to the 100HP and below Class 0 oil free market place. So in the event that an “oil free” solution like the Sullair DSP must be used, or is already in place; customers should consider installing early detection of oil content to prevent piping and process contamination. Air quality monitoring systems like our Beko Metpoint OCV will ensure that they maintain air quality that is in compliance with ISO 8573 for oil free quality air.

Looking to switch over to oil-free or oil-less air compressors? Northwest Pump sells air compressors in the Seattle and Washington regions, Oregon, Idaho and Montana. Reach out to Northwest Pump today – sales@nwpump.com or call 1-800-452-PUMP.