Avoiding faults and errors should always be top of mind when running large facilities. These mishaps lead to loss of production, unnecessary costs for repairs or replacement parts, and potential safety hazards for workers. While routine maintenance can lessen some of the likelihood of these errors from happening, the Chesterton Connect™ Intrinsically Safe Certified Sensor can help monitor equipment before the accident occurs.

The Chesterton Connect™ Intrinsically Safe Certified Sensor is designed to connect to machinery in hazardous environments and monitor their process pressure, process and surface temperatures, and vibration. All the data is then recorded and can be accessed through a Bluetooth-enabled app on a smartphone, Chesterton Connect. When a threshold is reached, an alert is sent to this smartphone, and the unit’s LED light display will activate- that way you and your workers onsite know when and where a problem is about to occur.

The Chesterton Connect™ Intrinsically Safe Certified Sensor is designed to connect to machinery in hazardous environments and monitor their process pressure, process and surface temperatures, and vibration. All the data is then recorded and can be accessed through a Bluetooth-enabled app on a smartphone, Chesterton Connect. When a threshold is reached, an alert is sent to this smartphone, and the unit’s LED light display will activate- that way you and your workers onsite know when and where a problem is about to occur.

With the data saved, you can export the information, allowing for analysis and preventing further malfunctions. Through the Chesterton Connect cloud platform, you can monitor the health of your equipment via an easy-to-use dashboard 24/7. The app allows analysis of variances and trends, adds notes, and takes action to increase uptime and productivity.

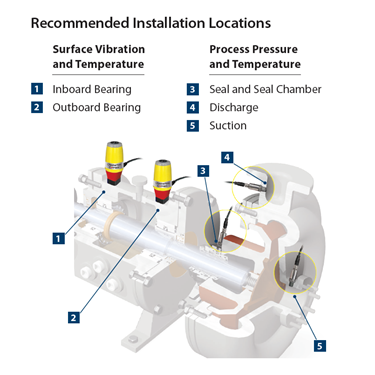

The device is installed via a magnetic base and a cable that can plug into several locations. This ensures that Chesterton Connect Intrinsically Safe Certified Sensor can closely monitor any machine’s problem areas.

This sensor is rated for Class 1/Division 1, Class 2/Division 1, and IP66 for outdoor use. In other words, this product was designed for work environments filled with gas, vapor, and dust in mind. Chesterton Connect™ Intrinsically Safe Certified Sensor also has safety features preventing the product from becoming a source of ignition.

This sensor is rated for Class 1/Division 1, Class 2/Division 1, and IP66 for outdoor use. In other words, this product was designed for work environments filled with gas, vapor, and dust in mind. Chesterton Connect™ Intrinsically Safe Certified Sensor also has safety features preventing the product from becoming a source of ignition.

Keep your workers and your facilities in the best conditions possible!

Click here for a free demo on the Connect IIOT solutions from Chesterton.