Sometimes, reliable solutions come in simple designs. So, why is it that for almost 70 years when people look at air-operated double-diaphragm (AODD) pumps they continue to ask about Wilden? Wilden sets its reliable AODD pump apart in five distinct ways: the variety of sizes & assembly styles, materials making up the pump, the number of parts used, the flow capacity, and the annual cost of ownership. Here is what makes Wilden stand out from its competition in providing reliable AODD pumps.

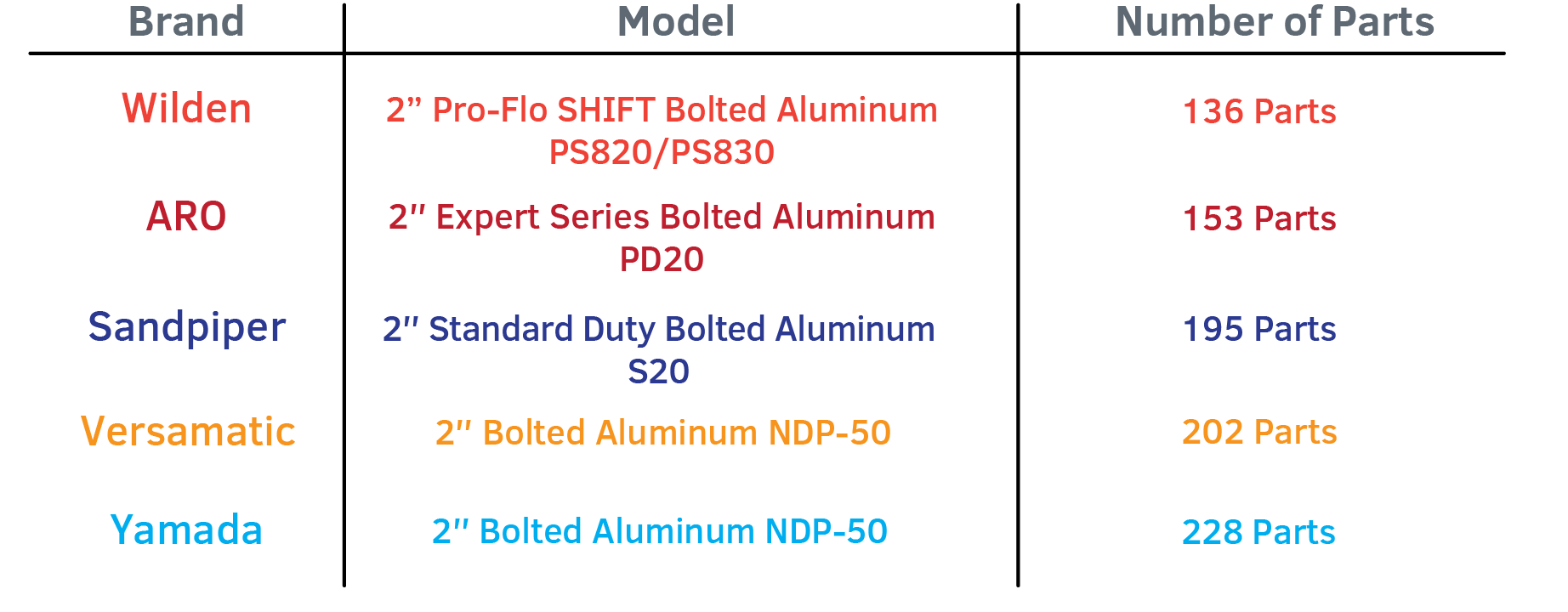

Number of Parts

Wilden offers its AODD pumps with as few parts as possible. This design creates a reliable AODD pump in a straightforward philosophy: less parts means less broken parts down the line. To showcase this, we can compare Wilden and its competitors. If we use a Wilden 2” Pro-Flo SHIFT Bolted Aluminum pump (referred to as a PS820) below, here is how many parts it has compared to the closest product from other AODD pump brands.

Data provided by PSG, a Dover Company

The PS820 has twenty parts less than ARO’s closest comparison. With twenty less parts, means twenty less potential areas for technicians to check for repairs, and more importantly, twenty less potential areas to break.

Available Assembly Styles & Sizes

Making sure that your pump is the size you need is an important part of buying industrial equipment. Additionally, AODD pumps typically are either bolted down or clamped. Bolting offers better fluid containment and efficiency as well as more output; but this style can often cost more than clamped pumps. However, clamped pumps offer easier access during maintenance without a sacrifice to reliability. So, how many styles and sizes do we see from the top brands.

Versamatic’s products were originally modeled after Wilden pumps, which means there is interchangeable parts between the brands. However, the ¼”, ½”, & 1” pumps do not have a clamped version. Additionally, Sandpiper’s Heavy Duty Ball design means that the end user will need to replace their current piping system with something more specialized. This process costs more and means that installation will be longer than plugging in the pump and letting it run.

Wilden offers its Pro-Flo Shift series in sizes ranging from ¼” to 3” in either bolted or clamped configurations. Additionally, Wilden also offers the Velocity series with compact ½” and ¼” sizes as well.

Materials of the Pump

Ensuring that the pumps’ materials are compatible with the pumped contents is critical to finding the right pump for a facility. Wilden offers a comprehensive chemical compatibility guide for end users to know what kind of material does not react to the pumped fluids. Wilden makes their metal pumps with aluminum, stainless steel, or ductile iron depending on the assembly style. With its plastic pumps, Wilden uses ‘virgin’ polyethylene, which protects against abrasive acids, making it a better choice for chemical processing. The material used for the wetted path or interior of the pump is the same throughout. This means that if the fluid being pumped does not react to the material of the pump, there is no concern for chemical reactions in any area of the pump.

However, there are other AODD pump brands that do not utilize these design features. For example, ARO offers plastic AODD pumps with a metal center section. This leads to potential chemical compatibility issues. Additionally, Yamada uses fiberglass to reinforce its polyethylene pumps. This can be especially dangerous when paired with aggressive acids, which can then wick through the reinforced areas.

Annual Cost of Ownership

Part of having a reliable AODD pump means that you can know how much that pump will cost per year. If we assume that a pump runs at eight hours a day, five days a week, we can compare costs across all brands. When all pumps are producing 140 gpm, ARO’s 2” EXP pump costs $2,715 annually. Yamada’s 2” NDP pump costs $3,757 annually. Wilden’s 2” Pro-Flo SHIFT pump costs $2,015 annually. This saves the Wilden customer $664 annually versus the ARO customer and $1,792 versus the Yamada customer. If we assume Graco’s 2” Husky & Wilden’s 2” Pro-Flo SHIFT are operating at 100 gpm, Wilden saves its customer $1,500 annually.

One of the factors contributing to the lower annual cost is a reduction in air consumption. Compressed air is often considered the fourth utility, so maximizing efficiency will contribute to a lowered bill every month. Wilden’s air consumption is anywhere from 24-48% lower than leading competitors, which translates to lower annual cost of ownership.

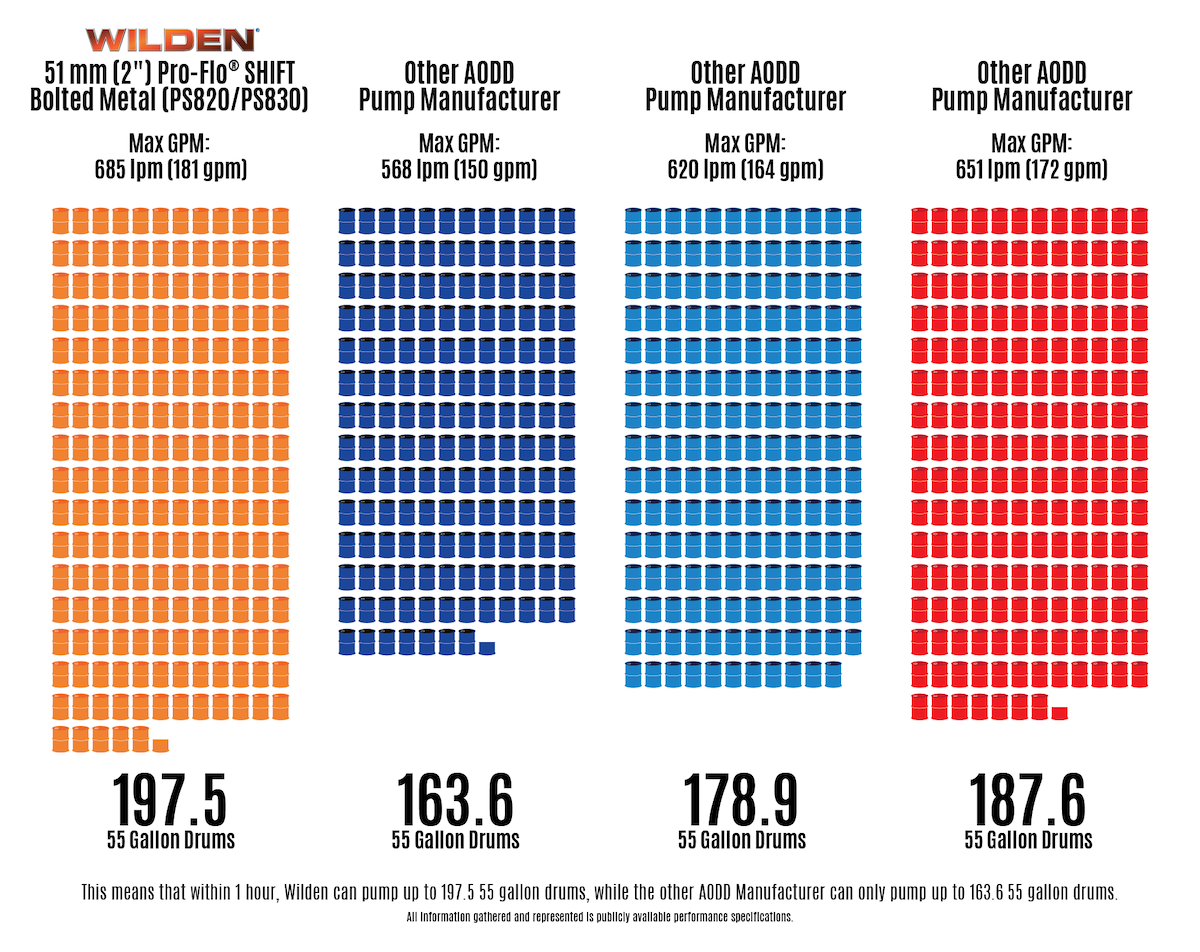

Flow Capacity

When buying a pump, having the best flow capacity for production is the key to success. If we compare 2” AODD pumps from Wilden and its 3 closest competitors, Wilden can pump 197.5 55 gallon drums of fluid in a single hour. The three competitors average together produce approximately 176.7 55 gallon drums.

Data provided by PSG, a Dover Company

Next Steps

With a philosophy of simplicity, Wilden produces a more reliable AODD pump than its closest competitors. This accomplished with a lowered cost of ownership with a maximized flow capacity, fewer parts than the competitor, and consistent materials used throughout the design of the pump.

Northwest Pump is offering a deal on Wilden pumps until the end of 2022. Trade in your current AODD pump from any Wilden competitor (ARO, Graco, Murzan, Sandpiper, Versamatic, Yamada, etc), and receive a 15% discount on your new Wilden pump. Alternatively, if you are upgrading your current Wilden pump, you can trade that in as well for a 15% discount as well. To take advantage of this amazing deal, click here to have our team contact you with next steps.

Looking for service on your AODD pump? Northwest Pump offers an in-house pump shop in our Portland branch. Request service for your equipment here.